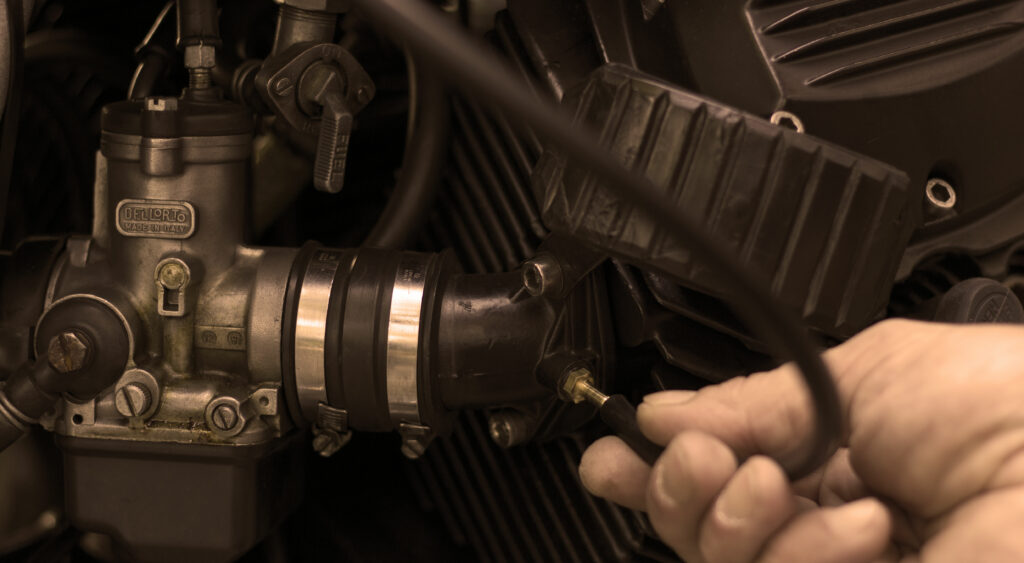

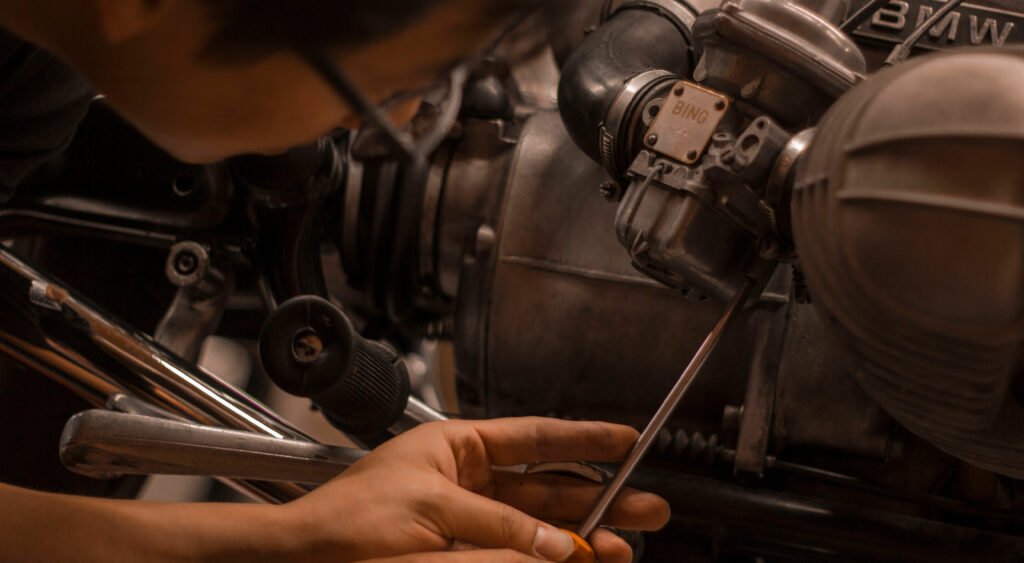

Why do carbs need balancing?

Synchronizing is adjusting the carbs (or throttles with fuel injection) so that each cylinder gets the same amount of air.

Smooth engine running

If exactly the same amount of mixture is sucked into the combustion chambers of the cylinders, the ignition of each cylinder causes exactly the same pulse on the crankshaft. This means that the motor runs smoothly and generates the lowest possible vibration.

Longer life

Vibrations stress materials and connection elements. This leads to premature fatigue. Deterioration of fits, premature leaks and even material fractures can result.

Perfect engine performance

The more evenly the cylinders deliver their power to the crankshaft, the more power is converted into the rotary motion of the crankshaft and thus into rapid propulsion. Vibration and chatter are wasted energy!

Crisp throttle performance

Uneven combustion is particularly noticeable during the transition from idle to partial load: the engine jerks. Perfectly synchronized engines respond well to the throttle and exhibit a harmonious, smooth transition without jerking.

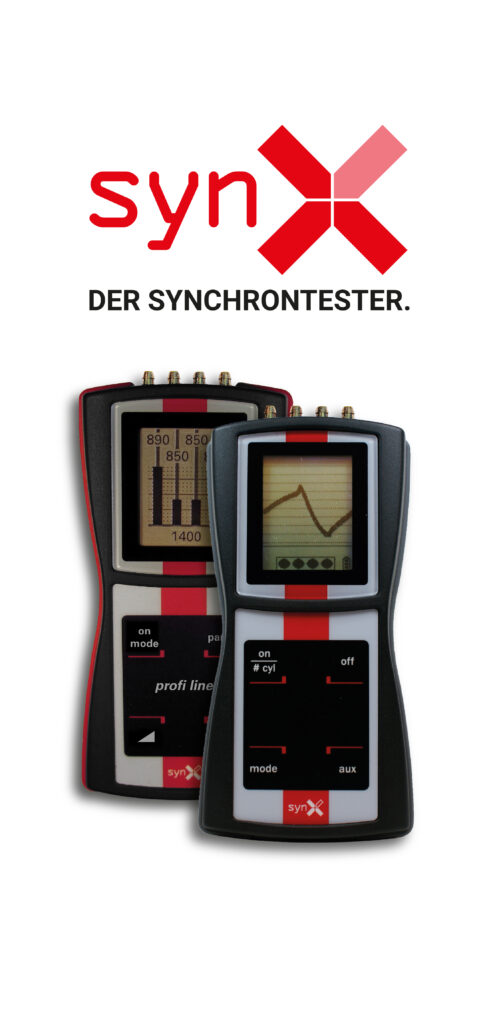

The Features

For optimal diagnosis, synX offers various types of measurement and displays. The display can be set for the simultaneous measurement of two, three or four suction tracts.

Absolute pressure

For all active channels, the suction vacuum is represented by bars and numbers

The bar display allows a quick assessment of whether a synchronization problem exists. With the adjustable, electronic display attenuation, it is possible to attenuate a disturbed display to such an extent that numerical values and bars are easily readable and the display nevertheless reacts quickly to changes. The lower display area always displays the current engine speed. Thus, the maintenance of the desired rotational speed can be easily checked during the measurement.

Differential pressure

The pressure differences between the individual intakte ducts are decisive for precise adjustment

The differential pressure display shows for each active measuring channel the positive or negative deviation with respect to the mean value of all active channels. This makes it particularly intuitive to work with. Up bar means: open throttle valve, down: close the butterfly valve. The longer the bar, the more it has to be adjusted. The adjustable sensitivity, like a zoom lens, allows you to touch the optimum balance.

Min-Max-Display (dynamic)

Not only the maximum intake vacuum, but also the span between maximum and minimum in the course of all four cycles should be approximately the same for all intake sections

For this purpose, synX can record the complete pressure curve and represent the range between maximum and minimum value. Major deviations between the cylinders indicate faults such as leakage.

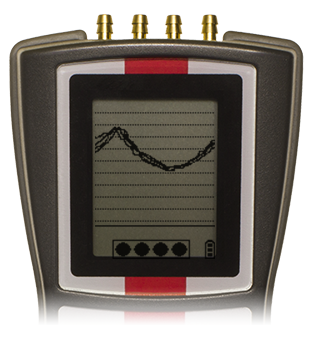

Pressure over time graph

For each active channel, the time curve of the intake vacuum is shown over all four strokes in a time-pressure diagram.

Each measuring channel can be individually displayed for an acccurate analysis. The visualiation of the pressure behaviour helpspressure helps to indicate leaks and defect valves. This is important for preventing sudden engine failures while driving.

synX classic or profi line –

the perfect choice for every requirement

The synX classic

You are an ambitiios amateur or have a small workshop and do synchronization from time to time?Then the synX classic is ideal for you, because you have the time and calm to get gradually through the measurement resolution and display attenuation.

The synX profi line

Synchronization is part of your daily business. For the fast synchronization process, we have developed a measuring range changeover and display that automatically adapts to the remaining pressure difference: AutoRang and AutoZoom. This saves you valuable time in your busy workshop life.

In summary:

While you have to switch display attenuation and resolution manually when synchronizing with synX classic, synX profi line does this work automatically thanks to AutoZoom and AutoRange. This saves the workshop professional valuable time. A higher measurement resolution of 1 mbar numerically and 0.25 mbar graphically provides the highest possible accuracy. The extra strong sensor heating ensures permanent availability and, in addition to battery operation, battery operation with voltage monitoring is possible (charging via USB with supplied power supply unit). A tank and seat support guarantee a non-slip hold in an optimal reading position. The entire professional set is packed in a sturdy plastic case.

Conclusion:

The synX classic is the right choice for amateur wrenches and smaller workshops, while the synX profi line is particularly well suited for frequent use in workshops with high vehicle throughput. It differs from the synX classic in its speed, even greater accuracy and special equipment for rough everyday workshop use.

Both synX classic and synX profi line deliver a precise synchronization result.

synX – passion meets technology

We give ideas for electronic products a real existence. We put our heart and soul into it and accompany our products from concept through development and design to production.

Our teams know every single one of the finely tuned production steps.

Automated quality controls ensure consistent quality even during the production process.

When a product finally leaves our factory, it is far from forgotten for us. We grant a 5-year warranty because we trust in the quality of our products. If a fault nevertheless occurs, we analyze and eliminate the cause as quickly as possible. At the same time, customer-oriented service is a matter of course for us.

Here’s a look behind the scenes: synX – THE MAKING OF

synX – MADE IN GERMANY

Product-Registration:

The synX-community

WE WANT YOU

Are you an enthusiastic synX user? Then show us your projects!

Whether two or four wheels, whether for the air or the water – send us your pictures or videos and you will appear in our synX community gallery!

The synX-Specialists

You have specific questions about synX synchronization or need expert help with a tricky setup problem?

The screwdriver specialists of our synX advisory board will be happy to assist you with their tips and many years of experience!